Stainless steel cable ties are an essential part of many industries, providing secure fastening and finishing solutions for a wide range of applications. In this blog, we will delve into the world of L-shaped stainless steel cable ties, explore what makes them unique, and emphasize the importance of the material used in the product. With their uncoated design, these cable ties offer exceptional durability and increased productivity, ensuring reliable performance in any project.

Learn about the versatility of L-shaped stainless steel cable ties:

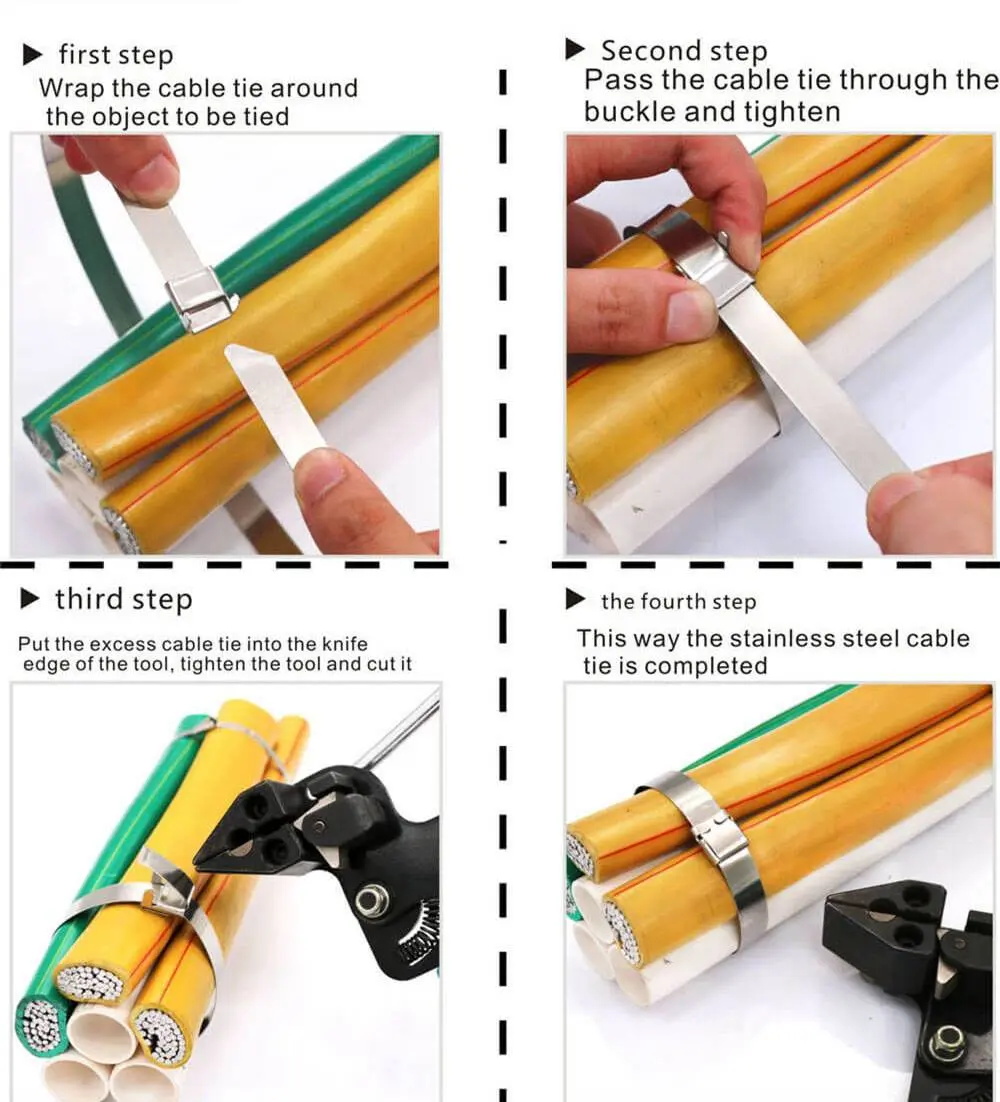

The L Shape Stainless Steel Ties really stand out because of their adaptability. Available in various widths, thicknesses and lengths, these cable ties can be efficiently customized to different project requirements. Its professional L-shaped buckle design increases the ability of the buckle to withstand the tension of the steel belt, providing safe and reliable binding for items of various sizes. This versatile design not only saves on-site installation time, but also improves overall work efficiency.

Uncoated but uncompromised performance:

One of the key features of the L-shaped stainless steel cable ties is its uncoated nature. While other breeds may come with coatings for specific uses, the uncoated design has unique advantages. These uncoated cable ties are manufactured from high-quality 201, 304, or 316 stainless steel. This ensures excellent weather and oxidation resistance, allowing long-term performance in challenging environments. In addition, the uncoated nature provides effective insulation and protection for the wires, increasing the safety and reliability of the overall setup.

Select materials according to project needs:

The material selection of stainless steel cable ties is very important, because it directly affects its performance and service life. L-shaped stainless steel cable ties, customers can freely choose 201, 304, 316 stainless steel materials. Each material offers unique advantages depending on specific project requirements. For example, 201 material has good corrosion resistance, while 304 material has excellent chemical resistance and high temperature resistance. The 316 material, on the other hand, is ideal for extremely harsh environments, ensuring unrivaled durability in the face of corrosive elements.

Meeting diverse binding needs:

Different projects require different binding strengths, and L-shaped stainless steel cable ties can also do this. The manufacturer understands the importance of meeting the individual needs of customers, offering a range of binding strengths. This flexibility enables professionals to select the appropriate cable tie strength for their specific application. This approach ensures that customers can achieve reliable and secure bindings regardless of the complexity or needs of their projects.

in conclusion:

L Shape Stainless Steel Cable Ties are revolutionizing the way we secure and organize things. With their unique design and high-quality materials, these cable ties provide excellent durability, insulation and protection. By incorporating L Shape Stainless Steel Ties into your next project, you can save time, increase productivity, and ensure long-lasting performance. Whatever the application, these uncoated cable ties stand the test of time and provide a reliable fastening solution. Choose L-shaped stainless steel cable ties to solve your binding needs safely and efficiently.

Post time: Jun-15-2023